THE PROBLEM

-

building process

largely manual building process: a) construction time is long; b) manual work is prone to errors that can cause unplanned problems, changes, and delays

-

safety

high risk of injuries (Swiss statistics for 2019 show 17 serious accidents per day and approximately 2 fatalities per month)

-

ecological efficiency

low ecological efficiency during their manufacture because of: a) the displacement of a high number of personnel, equipment, and materials to the construction site; b) a building technique which produces a significant amount of waste from supporting materials, such as packaging, formworks, construction timber, and others; c) the scarce use of recycled material in a broad and systematic way

KEY BENEFITS OF 3D PRINTING COMPARED TO TRADITIONAL CONSTRUCTION PARADIGM

Three-dimensional (3D) printing is an additive manufacturing process that creates a physical object from a digital design. The process works by laying down thin layers of a concrete mix which then ties up together. 3D printing allows to fabricate buildings or construction components in completely new shapes, which are not feasible with traditional concrete formwork. 3D concrete printing is an emerging technology, but still in a development phase.

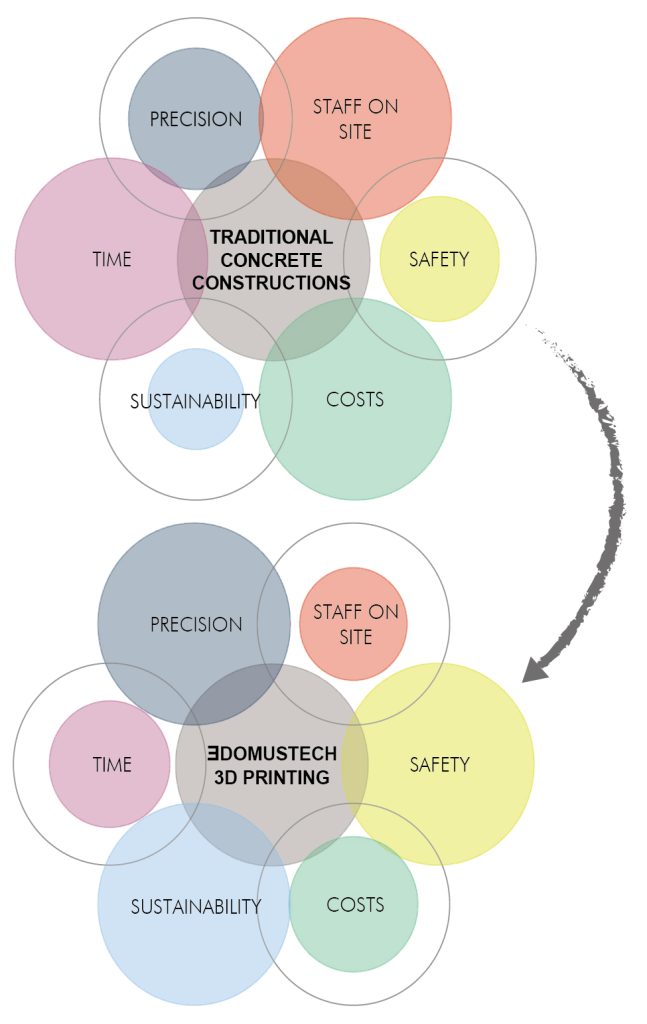

As shown in the picture above, the key differences between 3D concrete printing and the traditional construction paradigm are:

-

Precision

A 3D printer is designed to convert a digital design in a physical object. This is done with accuracy, repeatability, and reliability. The technique significantly reduces errors in the building and implementation phase.

-

Staff on site

3D printing requires a small number of specialized workers on site to oversee the automated construction process.

-

Safety

The reduced number of personnel on site and the type of job assigned to them greatly reduces the risk of serious accidents.

-

Cost

the construction process is more streamlined and efficient, and this leads to significant cost savings.

-

Sustainability

3D concrete printing increases the ecological efficiency during the building phase, significantly reducing the drawbacks previously highlighted regarding traditional construction, and enabling a systematic use of recycled materials.

-

Time

as mentioned, the construction process is more streamlined and efficient, and this leads to significant time saving. A 3D printer can be left running continuously in a nonstop building process.

A NEW BUSINESS MODEL AND CONSTRUCTION PROCESS

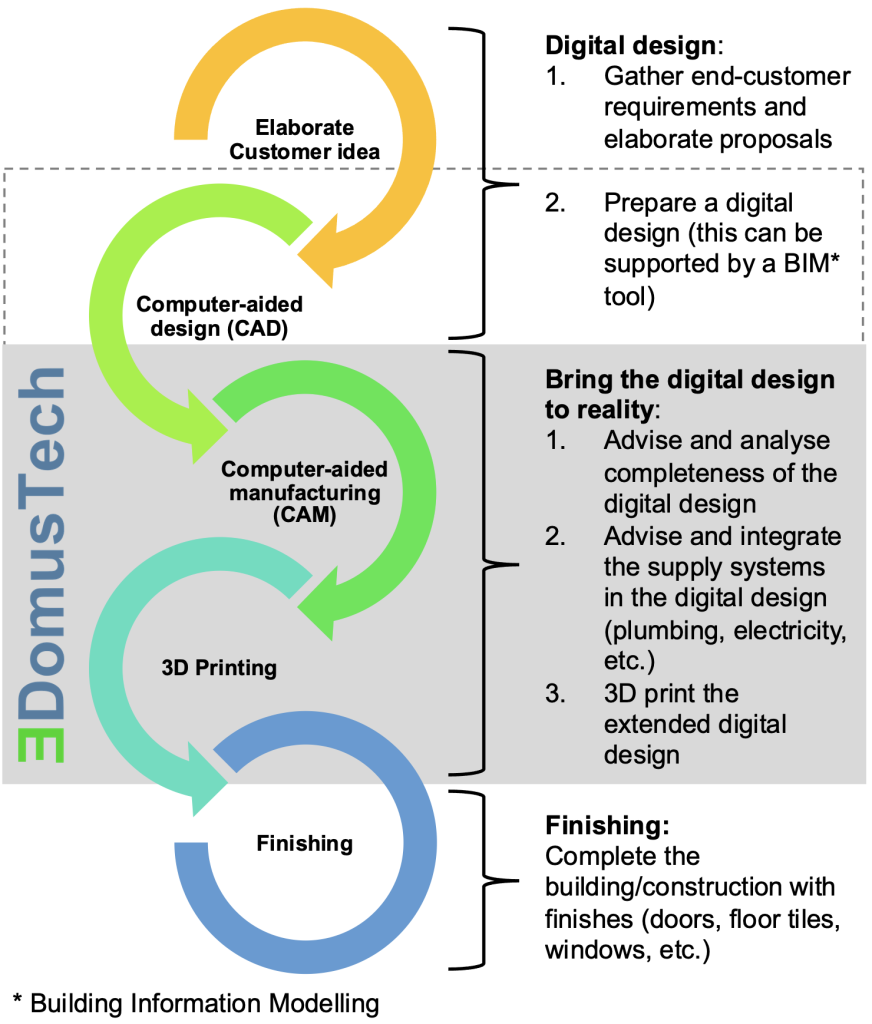

As shown by the following diagram, ƎDomusTech is positioned in the new construction paradigm which is based on a highly digitalized building process. With this new approach, more care is paid to analyse and collect the end-customer needs.

-

Digital design

The end-customer will be able to see the final result by means of 3D rendering and computer aided simulations, that can include positioning of lighting, light switches, power plugs, taps, etc. This first stage of the process, named in the picture as “Digital Design”, is not directly part of our business scope. Architecture/engineering studio, as well as construction companies, are already active in this context. ƎDomusTech can provide an “Architectural and design support” service to help in the digital design phase, especially in the early adoption stage of 3D printing to enable a faster move to the new construction paradigm.

-

Bring the digital design to reality

ƎDomusTech is positioned in the second phase of the diagram, named “Bring the digital design to reality”. It provides B2B service with the following channels: (A) Direct channel to Construction Firms – we target established construction companies that operate in the context of residential buildings, public works, and road building-yards; (B) Indirect channel to Suppliers of construction firms – we target suppliers of building material and tools that deal with smaller players in the construction sector (same context of the direct channel).

-

Finishing

The final stage of the process is the finishing that comprises the plastering and painting, the laying of tiles, installation of windows and doors, the plumbing installation, the installation of the electrical system, etc.. These activities are not part of ƎDomusTech’s business scope, since the construction companies to which we provide service are already active in this context.